Proven

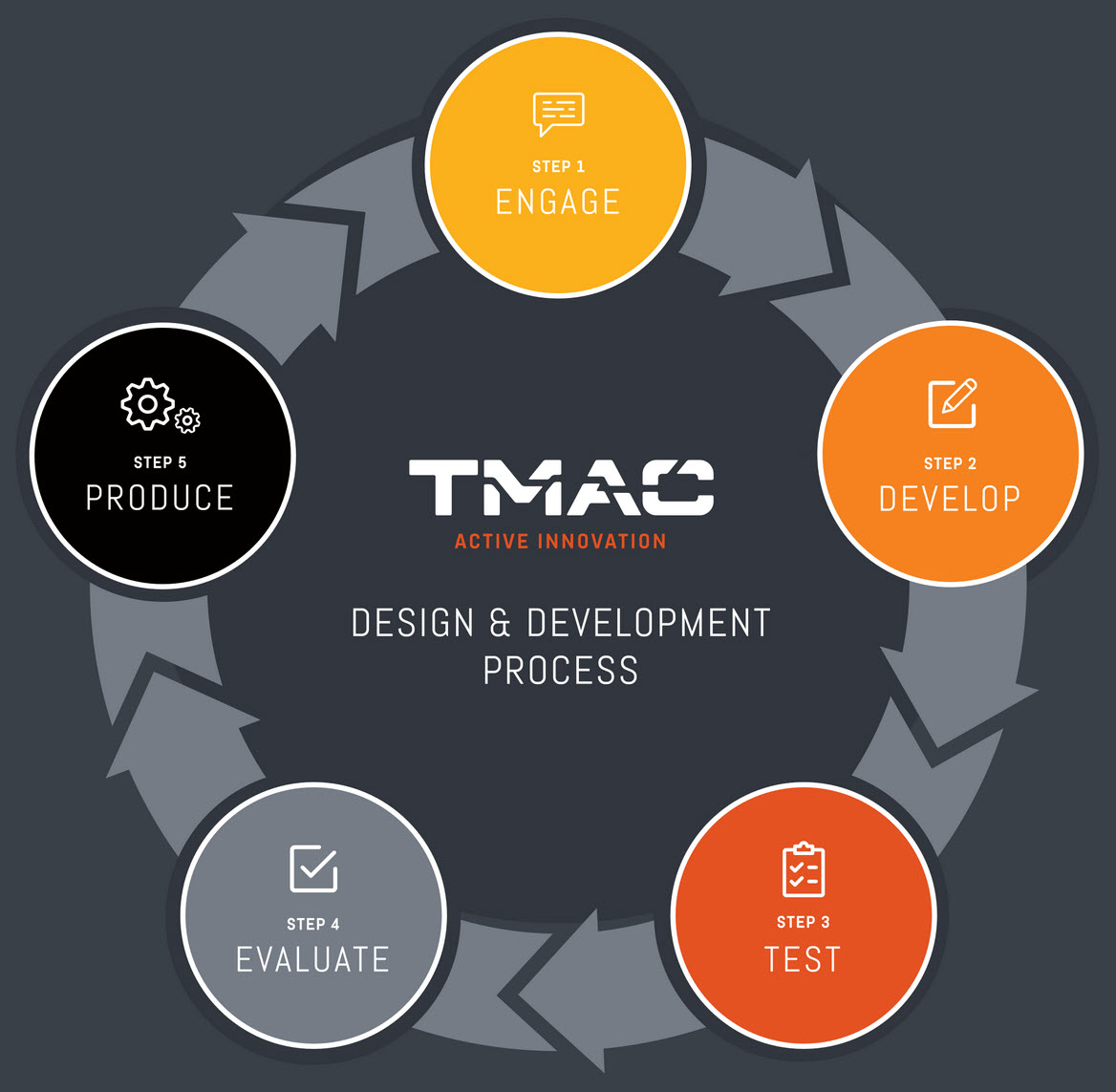

Design & Development Process

A proven Process

Having delivered many energy solutions for customers across the decades, we have defined a clear, five-step process to developing our innovative technologies. This systematic, coordinated approach ensures consistent results that meet industry standards.

From initial engagement with our customers, this process generally takes two – three months to complete.

Products designed and developed by TMAC for the Australian energy sector

Universal Pole Platform - UPP

Standing on the top rung of a ladder at the top of a power pole for hours at a time is exhausting and can be unsafe. TMAC developed the Universal Pole Platform (UPP), which attaches safely and securely to any power pole, allowing the operator to stand on a stable, safe, wide platform on a power pole for extended periods. The platform is insulated and tested to Australian safety standards.

Hazemeyer Earthing System

TMAC has developed a Hazemeyer Earthing System allowing the user to isolate each earth individually to conduct repairs and testing, while still maintaining safety.

DNOB - Do Not Operate Banner

When line crews attend a site, they cannot begin work until the link switch is open and the Do Not Operate Banner (DNOB) is applied to the power lines. TMAC have developed a DNOB applicator that completes both of these actions in one step.

Software Analysis and Type Testing

All TMAC designed and developed products undergo rigorous testing above and beyond what is required. Our commitment is to ensure all our products and if where possible succeed industry standards

- Mechanical Testing

- Mechanical (Destructive) Testing

- Electrical Testing

- Electronics Testing

Finite element analysis (FEA)

To demonstrate the thorough process undertaken for Type Testing in the case of mechanical type testing programs a Finite Element Analysis analysis is performed. This process is able to predict how a product reacts to forces such as heat, fluid, vibration and other effects.

The FEA is based on the initial design specifications. This allows the Design & Development team to ascertain if the design is likely to meet the customers specification in advance before the physical lab based type testing is conducted.